|

Lake Metal Culvert Co., Ltd

|

Corrugated metal pipe does better but saves money and time

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

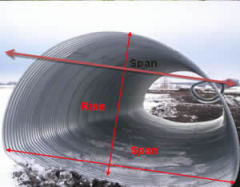

Corrugated metal pipes are designed in various corrugation profiles and diameters for different applications, such as culverts, bridges and storm sewe

Corrugated metal pipe is a perfect combination of strength, aesthetics, durability, economy and performance. An increasing number of engineers and designers tend to choose corrugated metal pipes for culverts, storm sewers, small bridges, grade separations and storm water detention systems.

Polymer coated corrugated steel pipe can serve 100 plus years

Corrugated aluminum pipe at manufacturing shop

Corrugated steel pipe installation spent two days containing the prepared work of one and a half days

Corrugated metal pipes are available in a series of corrugation profiles and wall thicknesses with the diameter up to 144". To extend their service lives, various protective coatings are provided, including galvanized, aluminized and polymer coated. Corrugated pipes can be fabricated by steel or aluminum which doesn't need protective coating. All these choices allow designers and engineers to choose the appropriate pipe in accordance with the practical applications.

Polymer coated corrugated steel pipe can serve 100 plus years

Corrugated aluminum pipe at manufacturing shop

Optional coating

Galvanized corrugated steel pipe, galvanized method is a standard way to enlarge life spans of steel products. Research shows that galvanized coating provide about 25 years of service period.Aluminized type 2 coating corrugated steel pipe offer excellent corrosion resistance against corrosive media and abrasive bedload. Its maximum life span can reach 75 years.

Galvanized corrugated steel pipe, galvanized method is a standard way to enlarge life spans of steel products. Research shows that galvanized coating provide about 25 years of service period.Aluminized type 2 coating corrugated steel pipe offer excellent corrosion resistance against corrosive media and abrasive bedload. Its maximum life span can reach 75 years.

Polymer coated corrugated steel pipe will withstand to aggressive conditions with high concentrations of acids and alkalis. Its perfect performances surpass any concrete pipes.

| Corrugated Metal Pipe | ||

| Part No. | Corrugations (pitch by depth) (inch) | Round Pipe Diameter(inch) |

| CMP01 | 1-1/2 × 1/4 | 6 - 10 |

| CMP02 | 2-2/3 × 1/2 | 12 - 72 |

| CMP03 | 3 × 1 | 48 - 102 |

| CMP04 | 5 × 1 | 48 - 144 |

Benefits:

Lightweight

Economical

Easy to install

Versatile

Durable

A series of sizes, thicknesses, materials and coatings to be chosen.

Deep corrugation adds strength to the pipe.

Lightweight

Economical

Easy to install

Versatile

Durable

A series of sizes, thicknesses, materials and coatings to be chosen.

Deep corrugation adds strength to the pipe.

Corrugated steel pipe installation spent two days containing the prepared work of one and a half days

Related Search

Metal Money Clip

Corrugated Pipe Production Line

Corrugated Pipe Line

Corrugated Pipe Extrusion Line

Galvanized Corrugated Steel Pipe

Corrugated Pipe Machines

More>>